Nov 24,2025

Strength and Load‑Bearing Capacity

When evaluating vinyl sheet piles for retaining walls or waterfront projects, one of the first questions is how their load‑bearing capacity measures up to traditional materials like steel or concrete. Vinyl (PVC or other polymer) is inherently less stiff than steel or reinforced concrete, but modern engineering practices mitigate this through smart design.

Steel sheet piles offer very high yield strength, often in the range of 250–350 MPa (megapascals), making them ideal for heavy-duty applications. Concrete walls, on the other hand, rely on their mass, reinforcement, and compressive strength (commonly 20–40 MPa for precast or cast‑in‑place walls), which make them very rigid and resistant to bending.

Vinyl sheet piles typically have a much lower modulus of elasticity (stiffness), but in many applications, that is acceptable because the soil or water behind the pile helps carry the load. Where high flexural demand exists, designers can increase the wall thickness, use interlocks, or add tie‑backs. In many moderate-duty applications like low to mid-height bulkheads, decking surrounds, or marine barriers, vinyl can be engineered to safely handle expected loads.

Durability and Corrosion Resistance

One of the strongest selling points of vinyl sheet piles is their excellent resistance to corrosion, rot, and chemical degradation. Unlike steel, which is vulnerable to rust (especially in saltwater environments), vinyl does not corrode and doesn’t require protective coatings or sacrificial anodes.

Concrete, while very durable, can suffer from deterioration over time due to carbonation, chloride attack, or freeze‑thaw cycles. Reinforced concrete may face rebar corrosion if not properly detailed or maintained. In contrast, vinyl is inert and maintains its integrity in a wide variety of environmental conditions.

Because vinyl sheet piles don’t rust or degrade biologically, maintenance costs over a 30‑ to 50‑year lifespan may be significantly lower than for steel or concrete, where corrosion protection, inspection, or patch repair are the norm.

Installation and Handling

Vinyl sheet piles are lighter than steel — this offers a practical advantage during transport, handling, and installation. Because of their lower weight, vinyl sections can often be installed using smaller lifting gear or even manual labor in tight-access areas.

In contrast, steel sheet piles are heavy, requiring cranes or heavy-duty vibratory hammers. Driving steel typically generates more noise, vibration, and risk of damage to surroundings. Concrete wall panels or cast-in-place concrete require forms, reinforcing steel, curing time, and sometimes large equipment.

Vinyl can often be installed by impact driving, vibratory hammers, or even pushing in softer soils, depending on design. Also, vinyl's flexibility means it can tolerate some misalignment or ground irregularities better than rigid concrete panels.

Thermal and UV Performance

Vinyl sheet piles are polymers and are susceptible to temperature changes. Under prolonged exposure to sunlight (UV), vinyl can degrade unless stabilized. However, high‑quality vinyl sheet piles are typically formulated with UV stabilizers (e.g., UV absorbers and HALS) which significantly improve longevity in exposed applications.

Thermal expansion is more pronounced in vinyl than in steel or concrete, with coefficients of thermal expansion roughly in the range of 50–70 × 10⁻⁶ /°C, depending on formulation. Designers must account for that in the joint design to avoid buckling or warping.

Steel and concrete experience far less thermal expansion under typical environmental conditions, but they come with their own challenges: steel may conduct heat and transfer thermal stress, while concrete can crack under freeze-thaw cycles. With proper design, vinyl can perform well over decades even with thermal cycling.

Environmental Impact and Sustainability

From an environmental perspective, vinyl sheet piles offer both advantages and trade‑offs. On the plus side, because they don’t corrode, their lifetime maintenance demands are low — reducing resource use over time.

On the other hand, PVC production has environmental concerns (e.g., chlorine content, energy use). However, modern formulations often use recycled content, and vinyl sheet piles themselves can be recycled at the end of their service.

Steel is highly recyclable and has a well-established recycling infrastructure, but the processes involved can be energy-intensive. Concrete is less recyclable in traditional settings, though crushed concrete can be reused as aggregate. Choosing the right material often involves balancing life-cycle environmental costs, not just upfront footprint.

Cost Comparison Over Life Cycle

Initial costs for vinyl sheet piles may be higher per linear foot than simple wood or uncoated steel, but often lower than high-performance alloy steels or heavily reinforced concrete solutions. However, the biggest savings typically arise over the lifecycle.

Here's a simplified comparison table of projected costs over a 30‑year life span:

| Material | Initial Cost | Maintenance Cost | Total Life‑Cycle Cost |

| Vinyl Sheet Piles | Medium | Low | Medium‑Low |

| Steel Sheet Piles | High | Medium‑High | High |

| Concrete Walls | High | Medium | Medium‑High |

Of course, these values are illustrative. Real-world costs depend on local labor, installation challenges, soil characteristics, and the exact vinyl or steel grade used. But it’s common for vinyl to be more cost-effective when factoring in long-term maintenance.

Resistance to Biological and Chemical Attack

Because vinyl is a polymer, it is naturally resistant to biological growth such as mold, algae, and fungi. This is a significant advantage in marine or humid environments. Steel, by contrast, may suffer biological fouling or rust-related issues if coatings degrade.

When exposed to certain chemicals (e.g., acids, salts, some solvents), vinyl performs very well compared to concrete, which can deteriorate under aggressive chemical exposure. Specialized vinyl formulations further enhance chemical resistance, making it a good option for industrial or harsh-water applications.

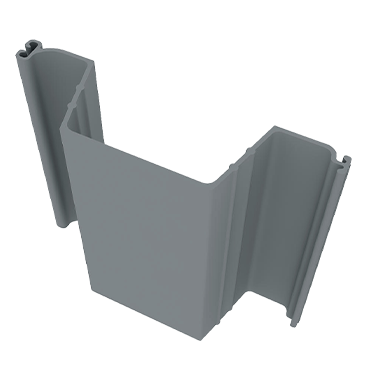

Design Flexibility and Customization

Vinyl sheet piles offer greater design flexibility. Manufacturers can extrude complex cross-sections, integrate interlocks, vary thickness, and even apply color or UV-stabilizer additives. These options allow designers to tailor the wall to project-specific needs.

Steel sheet piles are also quite customizable, but custom alloy grades or coatings may dramatically increase cost. Concrete can be cast in nearly any shape, but the formwork, reinforcement, and curing processes limit speed and flexibility.

With vinyl, the ability to pre-fabricate long, uniform panels with interlocks minimizes on-site labor and accelerates installation, making it efficient for certain modular designs or rapid construction schedules.

Longevity and Warranty Considerations

High-quality vinyl sheet piles, when installed properly, can last 30–50 years or more, depending on environmental exposure and maintenance. Many manufacturers provide warranties for decades, particularly in non-extreme settings. The inert nature of PVC helps it retain strength and resist degradation.

Steel sheet piles can also last many decades if adequately protected from corrosion by coatings, galvanization, or cathodic protection — but these protections require periodic inspection and maintenance.

Concrete structures, again depending on quality, reinforcement, and environmental conditions, can last 50 years or more, but issues like cracking, spalling, or rebar corrosion remain risks. Regular condition assessments and remediation may be necessary.

When Vinyl Sheet Piles Are the Best Choice

Based on the comparisons above, here are scenarios where vinyl sheet piles are especially advantageous:

- Coastal or marine environments where corrosion resistance is critical.

- Projects requiring minimal maintenance and long service life without coatings.

- Light- to medium-load retaining walls (e.g., landscaping, low bulkheads).

- Sites where installation equipment is limited due to access or noise constraints.

- Applications where thermal expansion can be accommodated in design.

- Projects with sustainability goals, especially if recycled vinyl is used.

That said, vinyl may not be suitable when extremely high structural loads are needed or rigid, heavy-duty solutions are mandatory.

Limitations and Challenges

Vinyl sheet piles are not without limitations. Their lower stiffness compared to steel or concrete means they may deform more under heavy load or highly variable conditions. Without proper joint design, thermal expansion can lead to buckling or gaps.

Another challenge is long-term UV exposure. Even with UV stabilizers, prolonged sunlight may affect material properties over decades, especially in very sunny or exposed sites.

Moreover, while vinyl is recyclable, its recycling infrastructure is not always as widespread or well developed as that for steel. End-of-life disposal or recycling must be considered during planning.

Conclusion

In summary, vinyl sheet piles offer compelling advantages over steel or concrete in certain applications — especially where corrosion resistance, lower maintenance, and ease of installation are top priorities. Their lower stiffness can be addressed through thoughtful design, and they can remain effective for decades when used appropriately. However, they may not be the optimal choice for very high structural demands or where rigid structural integrity is required.

Ultimately, choosing between vinyl, steel, or concrete sheet piling comes down to project-specific factors: environmental conditions, load requirements, installation constraints, life-cycle cost, and sustainability goals. For many modern applications, vinyl sheet piles provide a smart, durable, and cost-effective alternative to traditional construction materials.

English

English 中文简体

中文简体